Everything You Need to Know About GMP Compliance

Effectively operating a GMP-compliant facility poses unique challenges on top of those that every other facility manager or owner has to handle. If you own, manage, or use a GMP-compliant facility, there are some important things to know. We’ll cover everything, including how a company with Good Manufacturing Practice experience can make it easier to manage the facility.

What to Know About GMP Compliance

What Is GMP Compliance?

GMP (short for Good Manufacturing Practice) compliance is a system that ensures that products are produced and controlled to meet a certain quality standard. If you’ve ever wondered, “What is Good Manufacturing Practice,” you’ll find that a key part of it reduces risk and promotes safety in a facility.

You may also see GMP compliance referred to as cGMP, where the “c” stands for “current.” This naming convention highlights the need to stay up-to-date with the most recent protocols and regulations. cGMP looks at the most recent versions of the rules in the Code of Federal Regulation (CFR).

“What is GMP compliance” is a question that can also be answered by the way it can protect your company and your consumers. Customers are protected from microbes, other harmful contaminants, or chemicals in the products they purchase. The robust testing that comes with Good Manufacturing Practices delivers a better testing method than just examining samples. Meanwhile, your company reduces your risk of waste, losses, and recalls. More importantly, you reduce the risk of fines, seizure of products, or an interruption in production.

GMP compliance also improves the reputation of your company, revealing that you prioritize quality and confirming that you meet FDA requirements. Your customers can then have peace of mind and be encouraged to choose your company over those that are not GMP-compliant.

What Are the 5 Ps of Good Manufacturing Practices?

The Good Manufacturing Process standard can be broken down into the “5 Ps of GMP.” These “P”s stand for people, products, processes, procedures, and premises.

People need to understand their roles and responsibilities. Products must include clear specifications throughout every production stage. All processes should be documented, consistent, and simple. Procedures outline how to undertake critical processes. Finally, the premises should be clean and the equipment calibrated at all times.

Additionally, products apply to raw materials and finished products. You need to prioritize getting quality raw materials and storing them properly before they even enter the production line. It is also worth noting that the outlined processes and procedures must be strictly followed. Proper training for your workforce, including compliance training, can ensure this is the case. Standardizing procedures and processes ensures that your manufacturing is efficient and consistent in producing quality products.

How to Become GMP Compliant

If you haven’t achieved GMP compliance, it will typically take three to twelve months for you to do so. From there, you will need to make an ongoing effort to continue meeting requirements and stay up-to-date with changes or updates to it.

You can start this process by creating a team dedicated to ensuring the facility is GMP-compliant – this will likely entail working with contractors experienced in GMP-compliant facilities.

One of the first things to do is to assess your current operations and processes. This lets you identify practices that need to change before you can become GMP-compliant. You will also need to start documenting your processes, which is crucial to GMP compliance. Make sure you set up a method of keeping records, confirming that all the steps outlined in your procedures and processes are followed. You can achieve this manually or using recording instruments.

Once you think you are ready to officially become GMP compliant, do an internal audit. After getting your GMP certification, you must continue monitoring your facility, including equipment, processes, and staff. An essential part of continued compliance is training your team and hiring contractors that can comfortably work in GMP-compliant spaces. Remember that the FDA regularly checks for GMP violations, so you must continue to follow the relevant standards.

What GMP Compliance Applies To

GMP compliance applies to any controlled environment. It is extremely common in food and pharmaceuticals, as well as electronics and chip manufacturing. More and more facilities are working to become GMP compliant as they localize manufacturing. Others have realized that having their own facilities prevents delays in their processes. By maintaining their own GMP-compliant facilities, timelines in production are not affected or compromised by external factors that cause delays.

Who Is Involved in Maintaining and Building GMP-Compliant Facilities?

Any entity that builds, maintains, or renovates GMP-compliant facilities needs to understand its importance to a business. Some specific tasks are commonly overlooked but crucial to following Good Manufacturing Practice. Specifically, you must make sure you hire GMP-compliant contractors in projects involving a facility’s flooring, painting, and caulking.

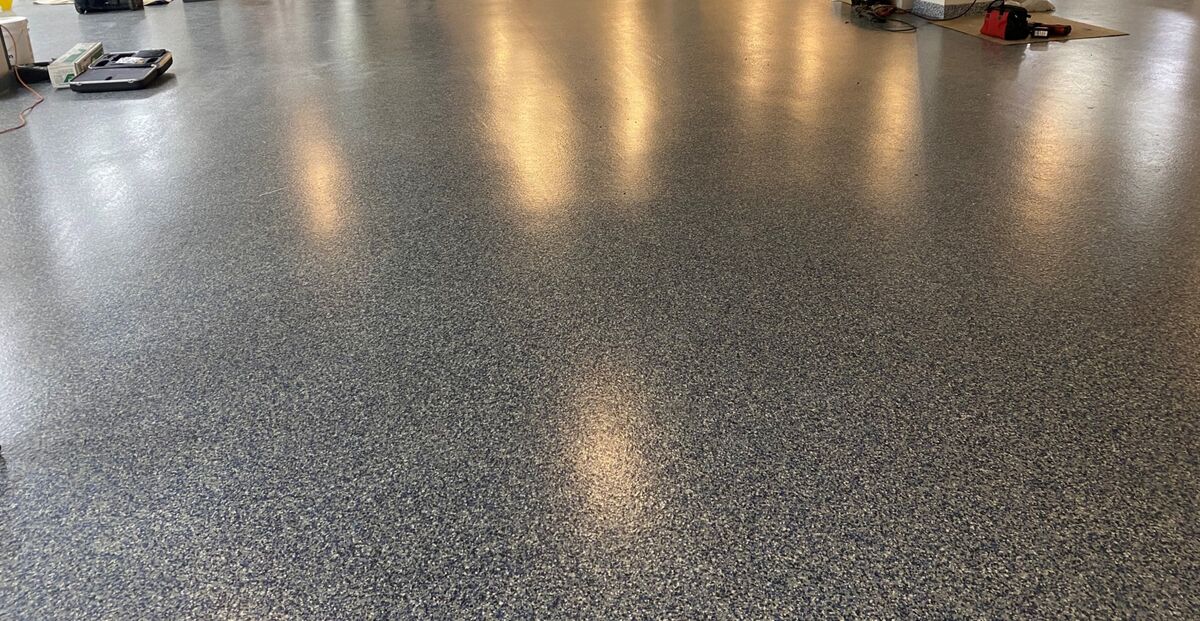

Flooring

A facility’s flooring is a major concern for GMP compliance. A big challenge is choosing the appropriate amount of aggregate. If you don’t include enough aggregate in the floor, you run the risk of incidents of slipping and falling. On the flip side, too much aggregate can tear booties and trap bacteria, which can cause an FDA flag and the entire operation to be compromised.

Another important consideration for GMP-compliant flooring is finding contractors who can turn it out quickly. After all, downtime hurts your productivity and profits, so a contractor that gets the job done swiftly is priceless. For example, you want to look for someone who can come in the afternoon and use polyaspartic materials that cure in an hour so that the space can be operational the next day.

Painting

One of the many considerations in regard to GMP compliance for painting is Spor-Klenz, which is a strong chemical for washing a surface. Using it frequently proves to be incredibly tough on surfaces. As such, your painting contractors must understand complex epoxies, including proper mixing and application.

Caulking

Caulking is also a precision job that requires GMP compliance training. You need to use the right FDA-approved 100% silicone caulk, especially on dissimilar surfaces and drop ceilings. This is a precision job that requires experience.

Carefully Choose Vendors for GMP Compliance

Due to the importance of GMP certification, you need to be careful when choosing your vendors and contractors. Most cleanroom contractors may be unfamiliar with your procedures and how to work in the space. As such, you want to choose a vendor that regularly works in cleanrooms and GMP-compliant facilities. Ideally, they will also provide GMP compliance training for their team, whether formal training or via extensive experience.

GMP Facility Maintenance

Once you understand what GMP compliance is, its effect on maintenance procedures should be a bit clearer. To put it into even more perspective, consider the size of bacteria. Most bacteria are between one and two microns. For reference, human hair is 100 microns, and the naked eye is unable to see 50 microns. Therefore, with the human eye alone, you have no chance of seeing the bacteria that needs cleaning to prevent it from accumulating.

You must educate your employees about these matters so they understand why following procedures is important. Remember that the end goal is to create a cleanable space that doesn’t promote bacterial growth. While there are commonly similar procedures across different facilities, there will always be some variation in each company’s systems.

Choose a Company That Stays on Top of GMP Compliance

The rules and best practices that make up GMP compliance occasionally change, making it all the more challenging. Even the constant rules and practices can be incredibly detailed and require a great deal of thought.

You can reduce the burden on your team by choosing a company that stays on top of GMP compliance. Kaloutas is highly experienced in this area. As we stay on top of your facility’s compliance, you can spend your time and effort on other important business matters. We also offer services in all the previously-mentioned areas that are important and challenging for GMP compliance, including flooring, caulking, and painting. Our GMP compliance strategies minimize or completely eliminate the need for downtime, reducing lost revenue commonly associated with upgrades or maintenance.

At the same time, Kaloutas can assist with other types of compliance, such as fireproofing and fire maintenance.

Kaloutas Makes GMP Compliance Significantly Easier

Let Kaloutas keep your facility compliant with the most recent GMP guidelines. From flooring to painting to caulking to GMP maintenance, we are happy to be your partner in following Good Manufacturing Practices.